|

Ningbo Emight Magnetics Co.,Ltd.

|

Magnetic Filter Grate Magnet Magnetic Assembly D300

| Price: | 300.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Magnetic Filter,Magnetic Grate,Magnetic Bar,Magnetic Assembly,Magnetic Liquid Trap,Grate magnets,magnetic tube,Magnetic Drawer,Bullet Magnet,

Why Choose Emight Magnetics?

● Provide hardware and plastic-related parts and components products, easy to purchase for you,can help you save logistics costs, to learn more information refer to Machined parts/Plastic parts.

● Produce high-performance products, stable performance, quality assurance, more details can refer to Quality center.

● Sintered Neodymium Iron Boron maximum magnetization direction can be produced at 60mm,Samarium Cobalt magnet maximum size can be produced at 120mmx120mmx100mm.

● Produce and process all kinds of OEM magnetic components.

● Sintered Neodymium Iron Boron and Sintered Samarium Cobalt magnets can be multi-pole magnetized.

● Sintered NdFeB magnet magnetic angle deviation degree can be controlled within 3 °,SmCo magnet magnetic angle deviation degree can be controlled within 2 °.

● One Stop Service from R&D sample design to mass production.

● Cooperated with 30 outsourcing factories with ISO certificates.

● Custom made magnetic systems available.

● Excellent after sales service.

Product Description:

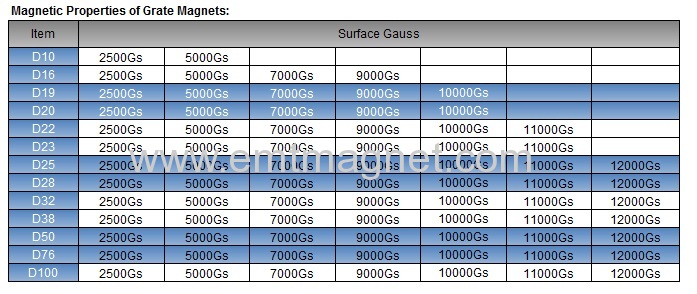

Brand Name: Magnet Bar,Magnetic Filter,Grate Magnets

Size: We mainly make custom shape and size magnets.

The magnetic filter is designed to remove micro-grade ferrous metals from various types of liquids of different viscosities. The filter assembly is based on the flow rate design, and the base of the easy-clean bar containing high-performance rare earth NdFeB magnets is contained in a stainless steel housing. Through its flange or quick release jig top into the design, the trap is easy to clean.

This filter ensures that the contaminants are maximally adsorbed on the high strength magnetic bar without obstructing the flow of the liquid.The filter can be used for any pipeline where the treatment liquid is at all levels of viscosity and can be mounted at any angle perpendicular to the horizontal direction.

A common placement is the tank loading and discharge to check the discharge and feed.Once the machine needs to be cleaned, just release the quick release band clamp, the grate magnets can be pulled out from the top, the ferrous metal will fall off. At this stage, all contaminants that are attracted can be easily removed, allowing for inspection or further analysis.

In addition, EMT also provides bullet-type magnetic filter, the bullet magnet is designed to be installed along the stainless steel pipe. When the dry, free-flowing product flows through the pipe, the contaminants are extracted onto the bullet. These devices effectively remove iron contamination from raw materials from powders or granules, flour, chemicals, plastics, food, pharmaceuticals and mineral materials. It provides magnetic protection for liquid piping and processing equipment. They protect the purity of the product by removing small contaminants so that such separators are ideal for liquid purification.

Application:

Magnetic filter are mainly used in food processing(Chocolate, Molases, Jam, Syrup, Juice, Sauce etc), fine chemical field, industrial area(lubricants, coolants, hydraulic oils, slurries in engineering) ,removing micron sized ferrous and para-magnetic contamination from various types of liquids, so as to achieve the improvement of material purity, to ensure material safety, enhance product quality.

Packaging&Shipping:

Packaging Details:Anti-magnetic and well protect in the delivery,

Standard packing carton: 34x24x375px.

Shipping:FEDEX, DHL, UPS, TNT ,By Air and By Sea etc.